Off. Address

1430. New GIDC, Waghodia, Vadodra

Have Any Questions

(+91) 91378 48856

Send Your Mail

Behind the Product

We work with a wide range of ferrous and non-ferrous metals to meet your exact project requirements which Includes:

Stainless steel

CRCA/HR/Galvanized

Copper

Brass

Aluminum

Our comprehensive services include:

-

Manufacturing of high-precision sheet metal pressed parts

-

Sub-assembly creation for various industries

-

Custom component design and development based on your specifications

-

Surface coating, Zinc, Zinc cobalt, Zinc blue passivation, Nickel plating, Silver plating, and Powder coating

-

Brazing of copper components for enhanced functionality

We offer flexible production volumes to cater to both large-scale projects and smaller custom requirements.

Quality

Reliable Industries is committed to delivering exceptional quality in every aspect of our work. We are ISO 9001:2015 certified, ensuring our processes adhere to the highest international standards. Our stringent quality control measures guarantee consistent precision and product performance.

Technology

Our state-of-the-art tool room and advanced machinery set us apart from the competition.

Our Process

The Reliable Industries Approach

At Reliable Industries, we pride ourselves on our meticulous approach to manufacturing high-precision sheet metal pressed components and sub-assemblies. Our comprehensive process, encompassing Exploration, Development, and Production, is designed to ensure that we deliver exceptional products that meet and exceed our clients’ expectations. Here’s a closer look at each phase of our process:

Understanding and Innovation

The journey begins with Exploration, a critical phase where we immerse ourselves in understanding our clients' needs and the specific requirements of their projects. This stage involves:

Client Collaboration: We engage closely with our clients to gather detailed insights into their objectives, challenges, and expectations. This collaborative approach allows us to tailor our solutions precisely to their needs.

Market Research: Our team conducts thorough research to stay abreast of the latest industry trends and technological advancements. This ensures that our solutions are not only current but also future-proof, keeping our clients at the forefront of their industries.

Feasibility Studies: We assess the technical and economic feasibility of potential solutions, ensuring that the components we propose will be viable and cost-effective for our clients.

Precision and Excellence

Once we have a clear understanding of the project requirements, we move into the Development phase. Here, our focus is on designing and refining components that meet the highest standards of precision and reliability:

Design and Engineering: Our experienced Tool designers and engineers utilise cutting edge software and technology to create detailed designs and prototypes. We ensure these designs meet all specifications and can withstand demand of real world applications.

Material Selection: We always select material as per requested by customer. we select materials that offer the optimal balance of strength, durability, and cost-effectiveness for each project. Our knowledge of advanced materials ensures that our components deliver superior performance and longevity.

Innovation and Customization: We are committed to innovation, constantly exploring new methods and technologies to improve our products. Whether it’s incorporating new materials or utilizing advanced manufacturing techniques, we strive to deliver customized solutions that set our clients apart from the competition.

Crafting Excellence with Every Component

once Tool designing is confirmed financials are confirmed we start with manufacturing of toolings and component samples are submitted for approval. This phase includes:

Advanced Manufacturing Facilities: Our state-of-the-art production facilities are equipped with the latest machinery and technology, enabling us to produce components with unparalleled precision and efficiency.

Scalability and Flexibility: Our production processes are designed to be scalable and flexible, allowing us to efficiently handle both small and large production runs. This ensures that we can meet our clients’ needs quickly and reliably, regardless of the size or complexity of the project.

Sustainability Practices: We are committed to sustainable manufacturing practices, minimizing waste and reducing our environmental impact. Our focus on sustainability ensures that our clients receive not only high-quality products but also the peace of mind that comes with responsible sourcing and production.

Among our key technological advancements is the adoption of specialised resistance brazing, a process developed for joining copper to copper components with precision and consistency.

This process is carried out using a specially designed Special Purpose Machine (SPM) procured for our operations to cater to the specific requirements of the electrical industry.

The system enables superior joint quality, enhanced efficiency, and reduced production time, strengthening our capability to deliver high-performance solutions.

Tool Room

We boast a dedicated tool room equipped with

the latest technology for in-house tool and jig

design and manufacturing.This ensures:

-

Faster turnaround times

-

Improved cost-efficiency

-

Enhanced control over quality

Other Equipment

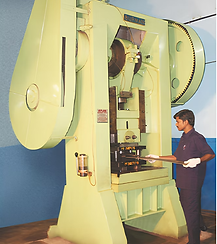

Our production facility utilizes a diverse range of high-performance machinery, including:

-

Mechincal presses upto 100 Tons

-

Hydraulic press upto 50 Tons

-

Pneumatic power presses

-

Shapers, Grinders, Power Shears and Milling Machines

-

Lathes, automatic tapping machines, and drilling machines

-

Specialized Drilling, Tapping SPM's and many other SPMs for copper cutting, brazing, and spot welding